If you’ve noticed flickering lights, mysterious power dips, or equipment that refuses to cooperate, you should know that these are subtle clues telling you that something isn’t right with your electrical system. In an industrial setting, they can snowball into serious operational issues or even safety hazards if left unchecked. Understanding the common electrical issues in industrial buildings is the first step toward creating a safer, more efficient environment for everyone involved.

You must be wondering what lies behind those concrete walls and steel panels—wiring that hasn’t been upgraded in years? Panels overloaded with modern machinery? You’re not alone.

Industrial facilities often operate for years without reviewing the health of their electrical systems, and it’s not until a failure occurs that the alarm bells start ringing. But by that point, damage to equipment—or worse, to people—may already have been done.

At Edison Electric Services, we’ve spent decades helping Winnipeg’s industrial clients uncover and resolve these hidden problems.

From outdated panels to poor grounding, our experienced electricians diagnose, repair, and future-proof your systems.

In this blog, we’ll walk you through the common electrical issues in industrial buildings, why they matter, and how we solve them—before they turn into costly disruptions.

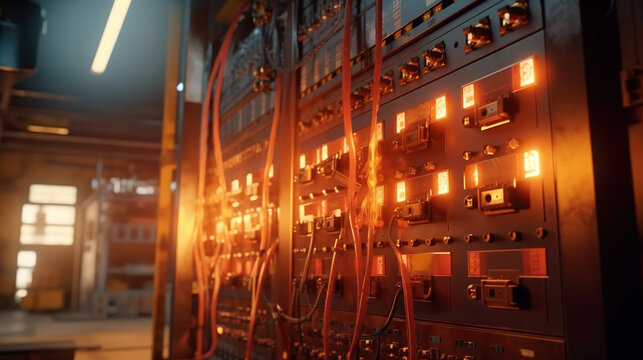

Outdated or Overloaded Electrical Panels

We are certain that you’d want to know if your entire production line could be at risk due to something as basic as an outdated panel. Many industrial buildings still rely on legacy systems that were installed decades ago. These panels weren’t built to handle modern machinery, let alone high-efficiency equipment that draws variable loads. Overloaded panels can lead to frequent tripping, overheating, and, in severe cases, electrical fires.

But how do you know your panel is outdated? You should look for signs like tripping breakers, dimming lights during equipment startup, or panels that feel warm to the touch.

At Edison Electric Services, we replace aging panels with code-compliant solutions designed for today’s industrial demands, ensuring safety and reliable operation.

Poor Grounding and Bonding

You must be thinking all your equipment is safely connected. However, poor grounding is one of the most common electrical issues in industrial buildings, and it often goes unnoticed until something malfunctions. Without proper grounding, electrical surges can damage sensitive equipment, interrupt processes, and pose a serious shock hazard to employees.

We often find inconsistencies in older facilities where additions were made over time without harmonizing grounding systems. Our team thoroughly assesses all grounding and bonding connections, bringing your facility up to CSA and Manitoba Electrical Code standards. Proper grounding improves the performance and longevity of your machinery.

Faulty Wiring and Deteriorated Insulation

You’d be surprised how many critical systems are relying on wiring from a bygone era. Faulty, frayed, or corroded wires can result in voltage fluctuations, frequent outages, or unexpected equipment shutdowns. Over time, even well-installed wires deteriorate due to exposure to heat, vibration, or chemicals common in industrial environments.

Industrial facilities often house wires running through conduits in hard-to-reach spaces, which means these issues can go undetected for years.

Our licensed electricians specialize in inspecting and replacing industrial-grade wiring. We upgrade your system to withstand the environmental conditions of your workspace.

Inconsistent Voltage or Power Quality

If you’re wondering why your machines sometimes slow down or perform inconsistently. We have an answer for you. Poor power quality, including voltage dips, harmonics, or transients, can interfere with programmable logic controllers (PLCs), motor drives, and sensors. In industrial settings, this can lead to process delays, product defects, and increased wear on equipment.

We use professional-grade diagnostic tools to analyze your facility’s power quality and trace issues back to the source—whether it’s internal wiring or utility feed inconsistencies. Solutions like power conditioning units, voltage regulators, and panel upgrades are part of our toolkit to restore consistent power flow to your operations.

Loose or Corroded Connections

Industrial electrical systems are subject to continuous vibrations from machinery and environmental factors like humidity or chemical exposure. Over time, connections can loosen or corrode, creating high-resistance points that generate heat and invite failure.

Routine maintenance is key, and that’s where Edison Electric Services steps in with scheduled inspections and infrared thermographic scans to detect hot spots before they cause serious damage. We tighten, clean, and replace affected connections, preventing breakdowns before they start.

Conclusion

If you’re thinking that it’s time for a comprehensive electrical inspection, you’re right. These common electrical issues in industrial buildings can have a significant impact on safety, productivity, and cost. But the good news? They’re entirely preventable when you partner with the right professionals.

At Edison Electric Services, instead of responding to breakdowns, we help you stay ahead of them. Whether you’re operating a manufacturing plant, processing facility, or warehouse in Winnipeg, our licensed electricians provide the insights, upgrades, and preventative solutions you need.